Helping factories

plan smarter

move faster

cut delays in production

with Ziso Zero

with Ziso Zero

Helping factories

plan smarter

move faster

cut delays in production

ZISO Zero powers Zetwerk’s $10B manufacturing network, with 100+ projects monthly, tracking suppliers, materials, and production timelines. I led the redesign of ZISO Zero, rebuilding it as a flexible system that unites planning, tracking, and delivery across Zetwerk’s operations.

My Role

Senior UX Designer

Timeline

5 months

2021

Company

Impact

+236 % Adoption

Team

Senior Product Designer (myself)

2x Product Manager

3x Planning Engineer

4x Program Managers

5x Developers

3x QA

WHY MANUFACTURING PRECISION MATTERS?

Every delay costs more than time

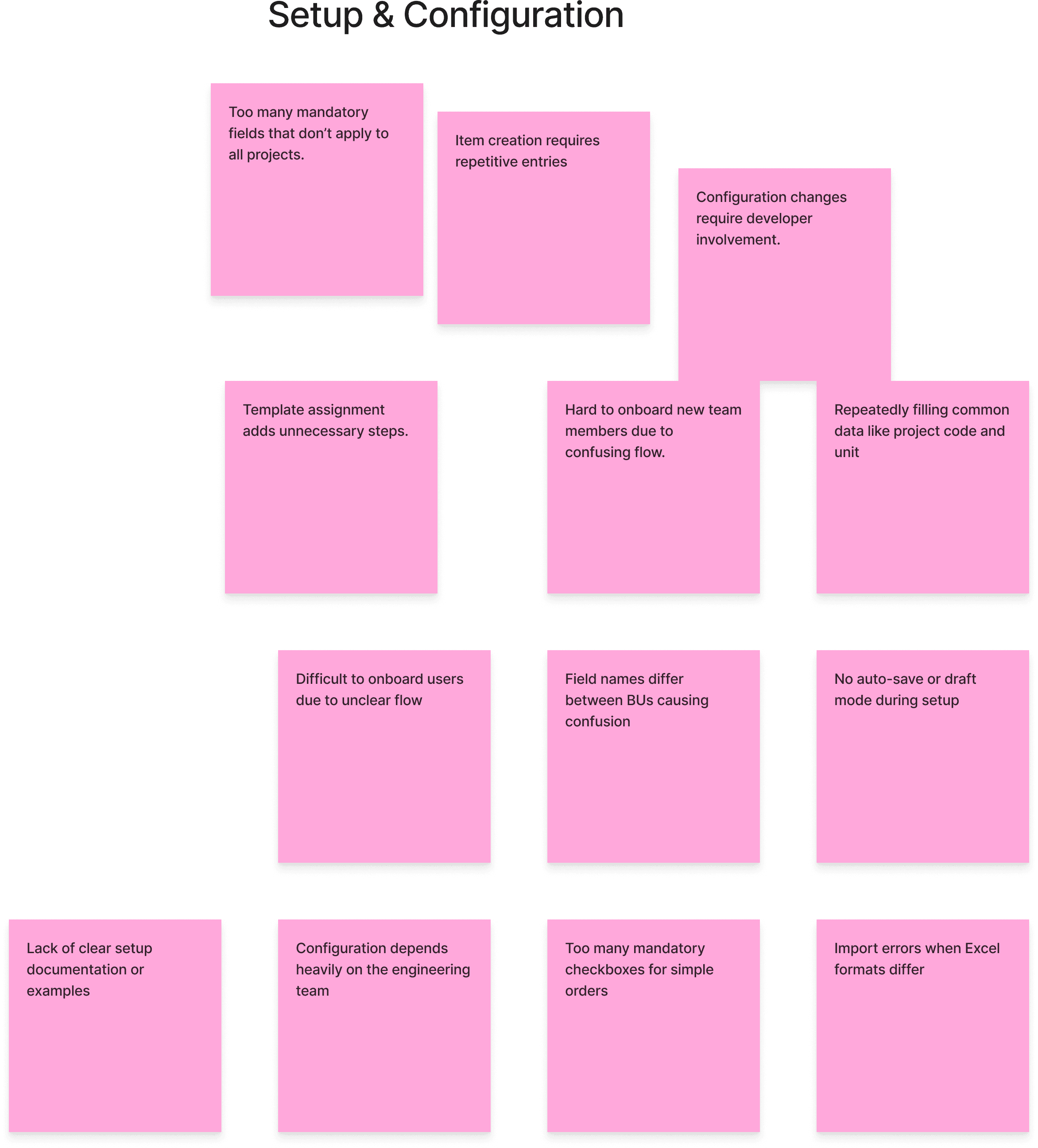

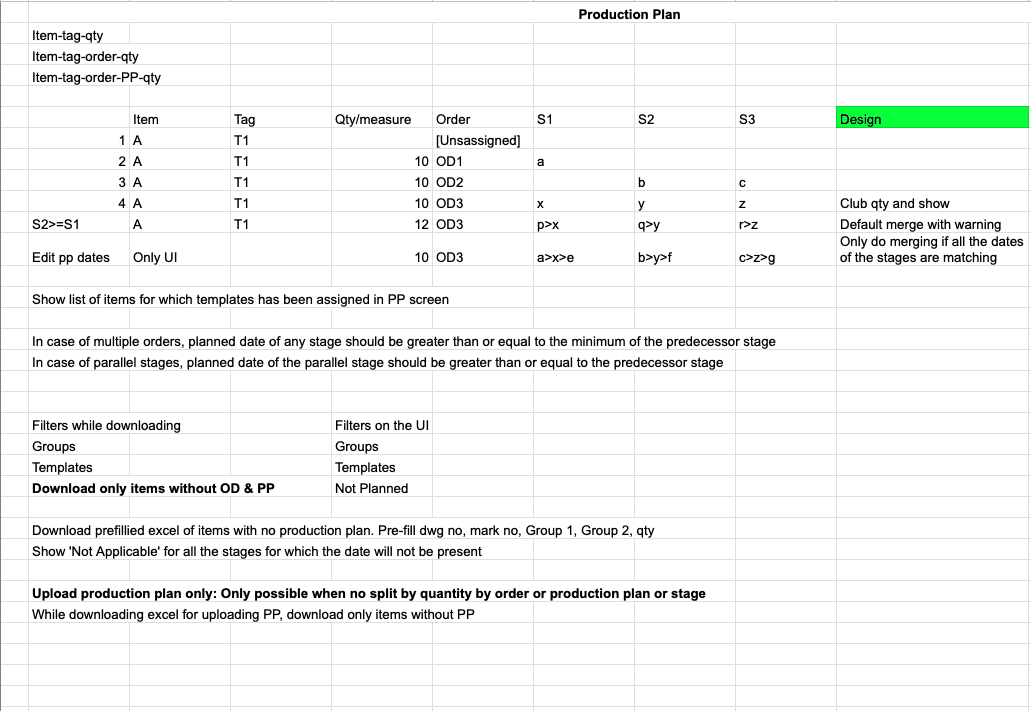

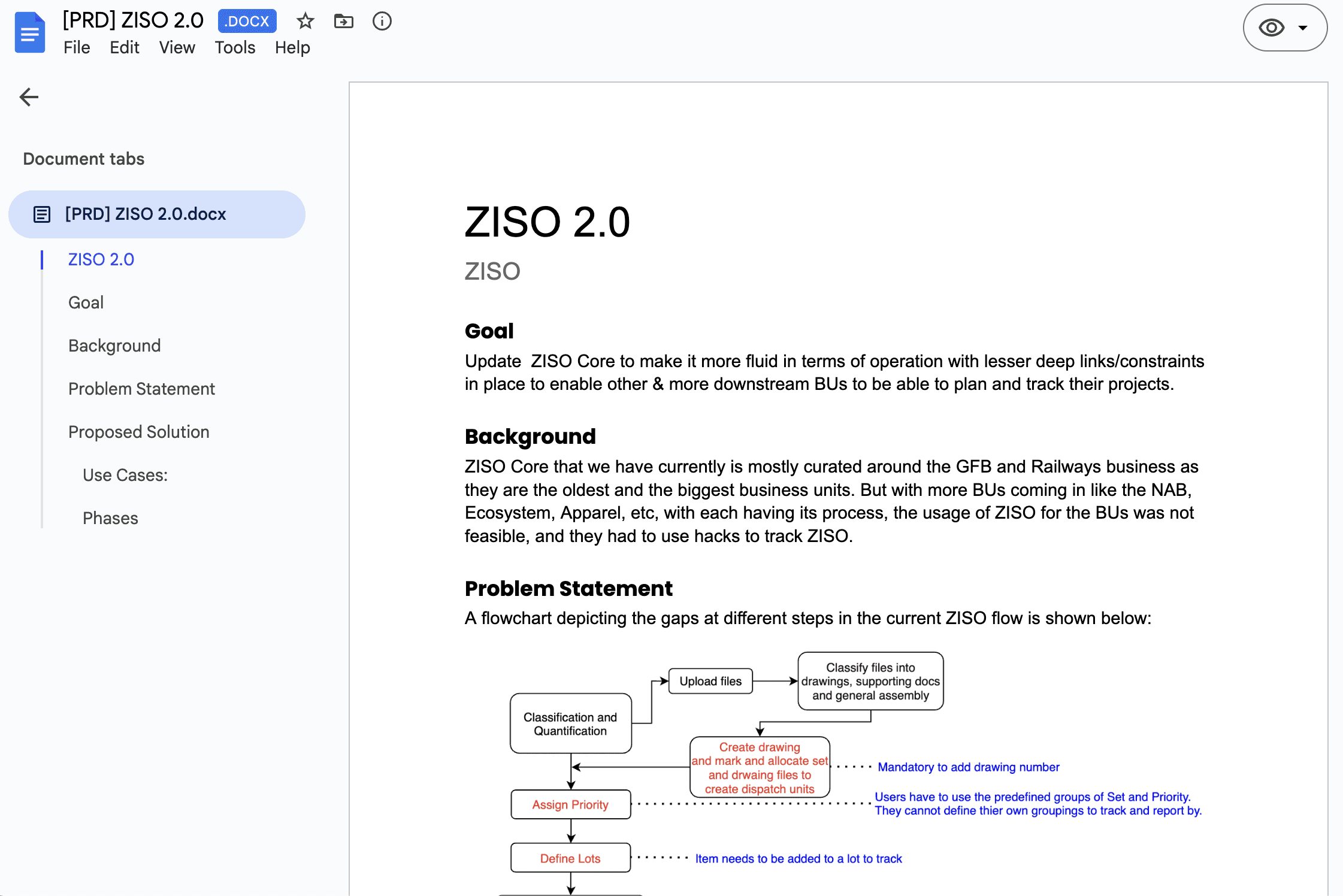

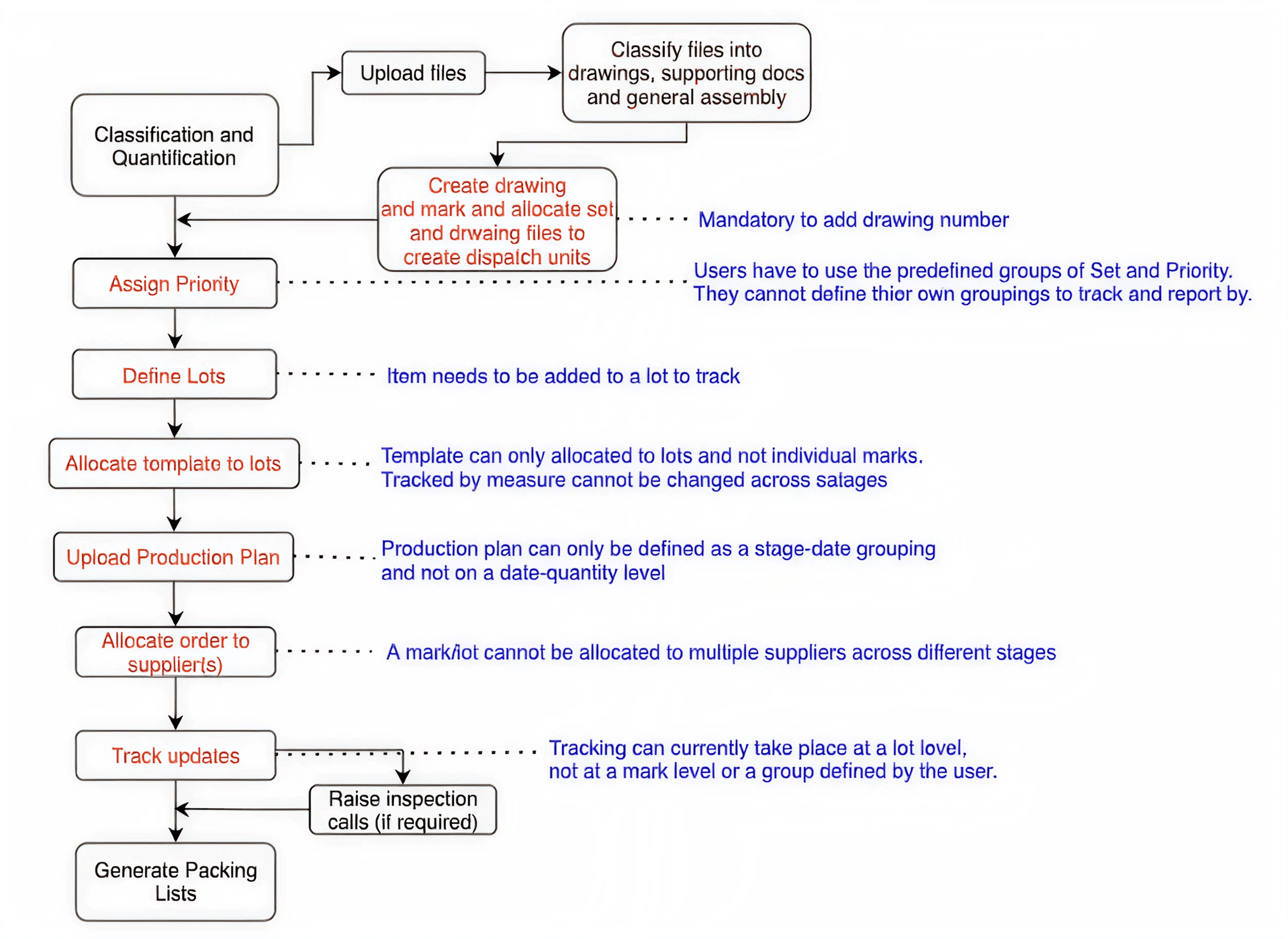

ZISO Zero was designed for a single business unit but couldn’t flex with new workflows. As more teams joined, planners struggled to fit their processes into a one-size system, leading to frustration, lost time, and disconnected data.

Each team had different needs, but one shared problem: the system’s structure could not match the pace of manufacturing.

PROBLEM

A system built for structure couldn’t scale with speed

ZISO was designed for a single business unit and couldn’t flex with new workflows.

As more teams joined, planners struggled to fit their processes into a rigid structure.

The result was lost time, disconnected data, and frustration across units.

Interviews across four operational barriers that limited adoption:

6

hrs

PLANNING ENGINEERS

Spends on creating “dummy lots” to track a single item.

2

days

PROGRAM MANAGERS

Relied on Excel and WhatsApp for visibility, delaying updates by 1–2 days.

65%

Contracts

OPERATIONS TEAM

Couldn’t assign multiple suppliers to different manufacturing stages, causing coordination gaps across production lines.

16%

PROJECTS

Fully tracked inside ZISO.

The rest existed in scattered sheets and emails.

SOLUTION

Rebuilding ZISO as a flexible and

modular system

ZISO 2.0 was redesigned to scale horizontally while preserving manufacturing precision.

01

Bulk Create and Track

I designed Bulk Create to help planners define and modify multiple lots at once, reducing setup time across orders.

An Excel-compatible interface mirrored existing habits while automating validations, letting teams upload and track thousands of items in one go.

Teams needed a faster way to define and modify multiple lots simultaneously.

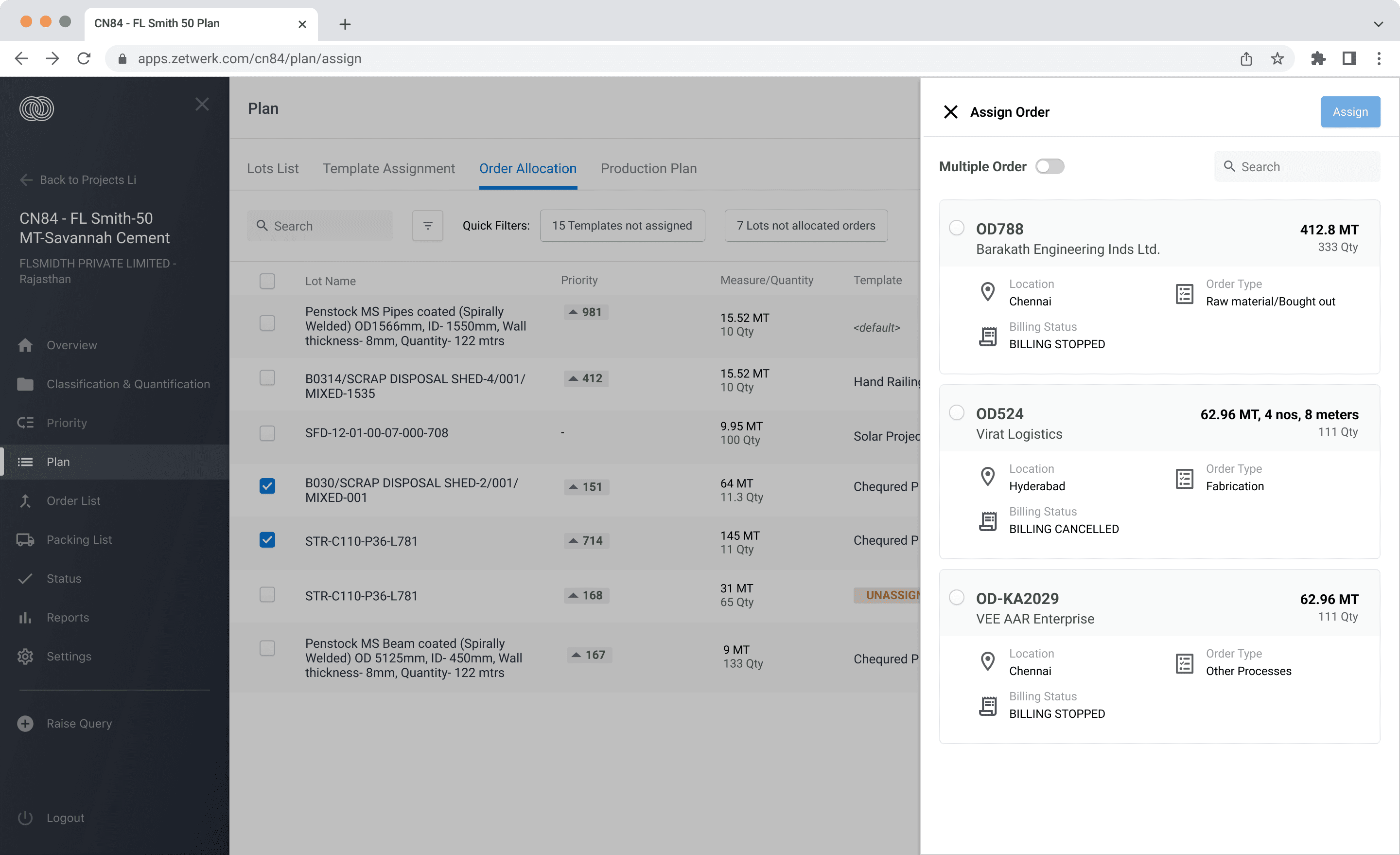

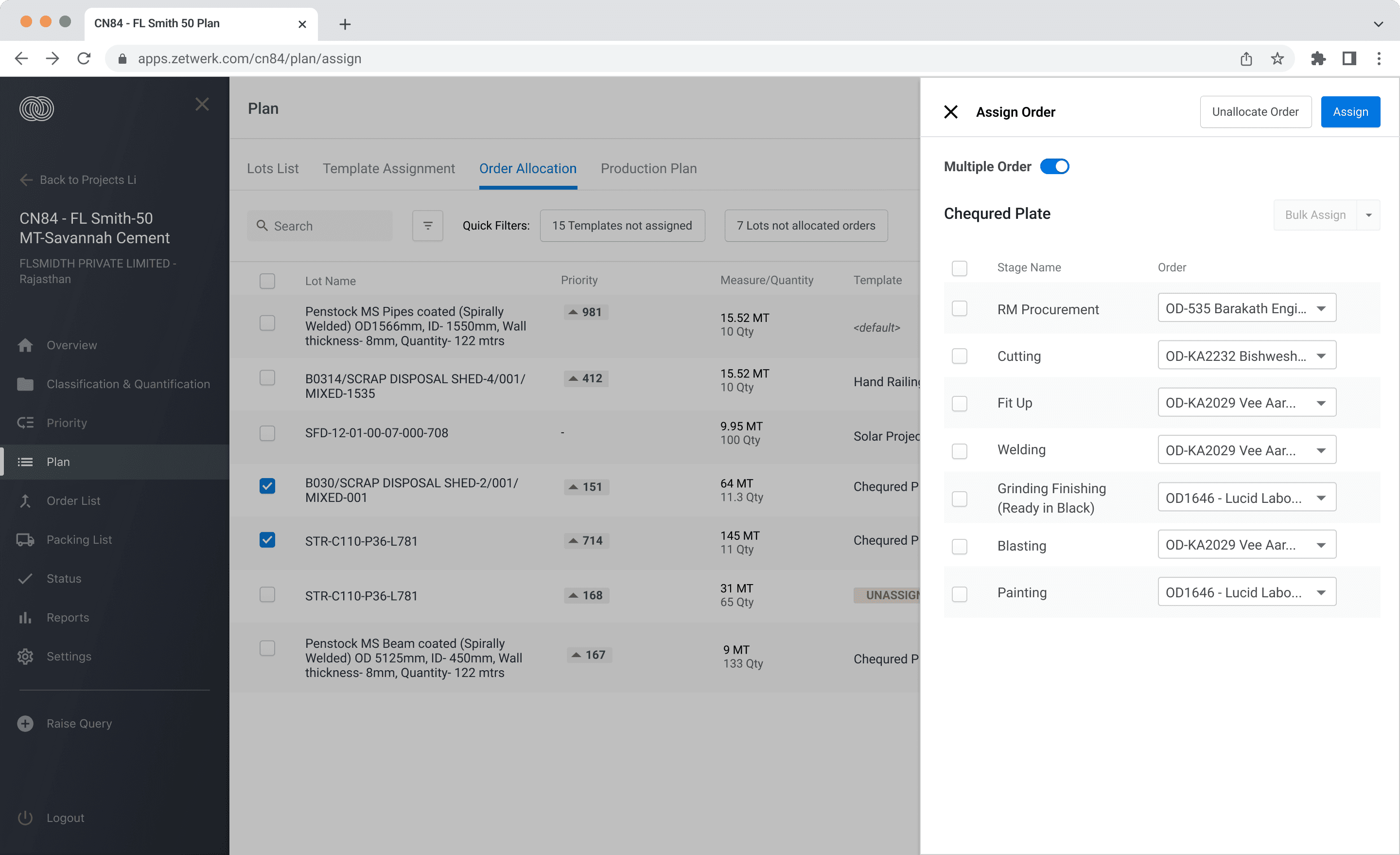

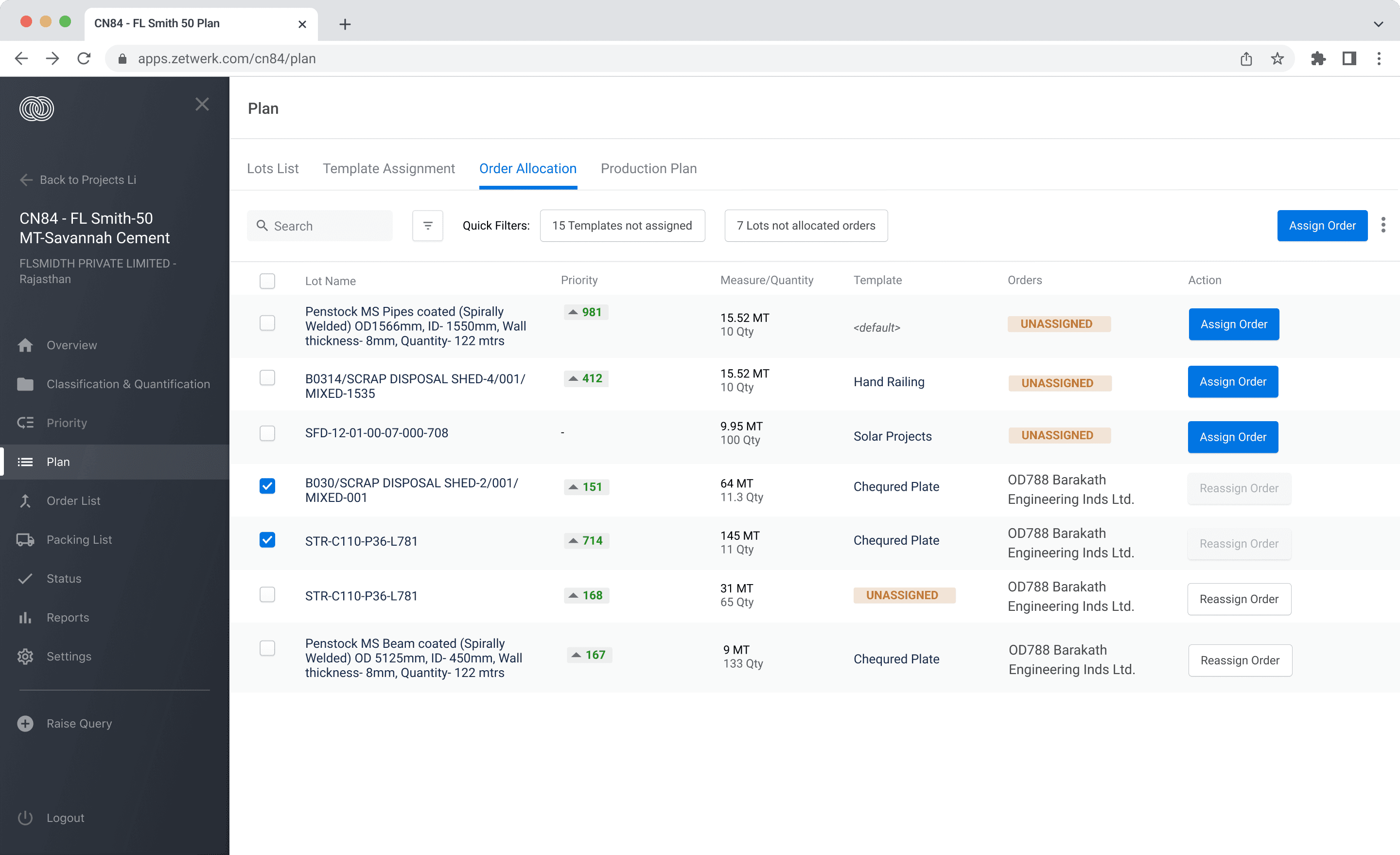

02

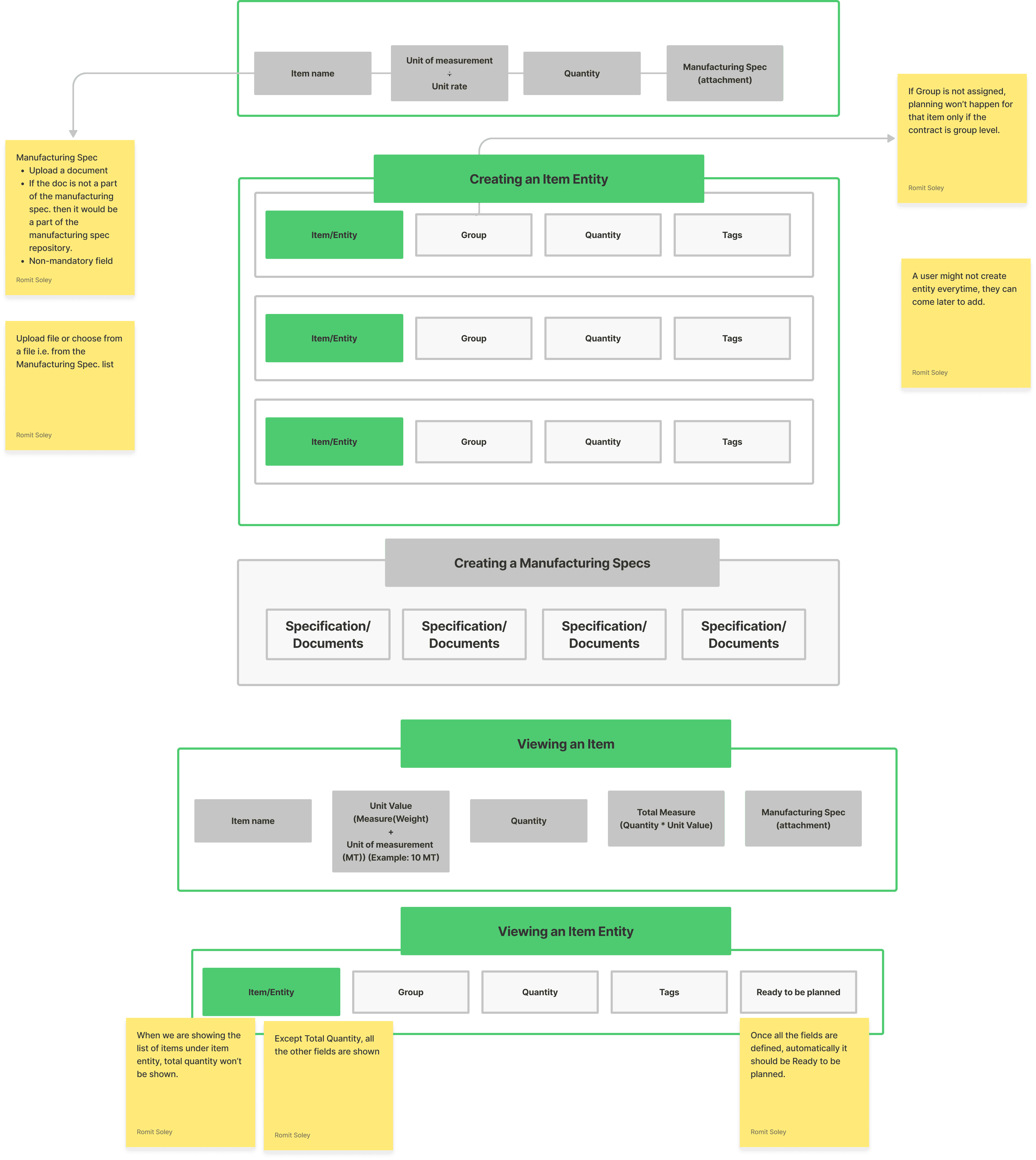

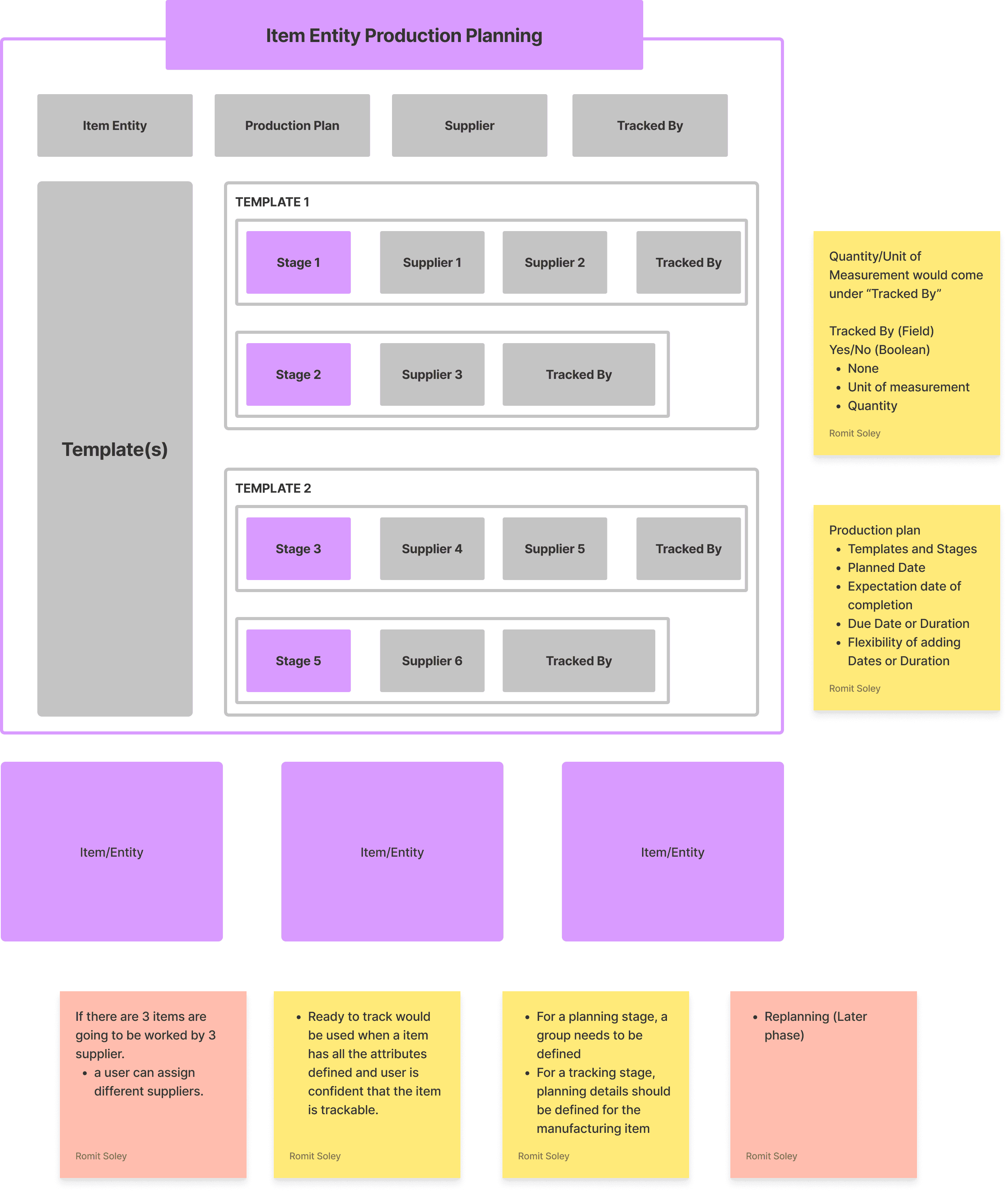

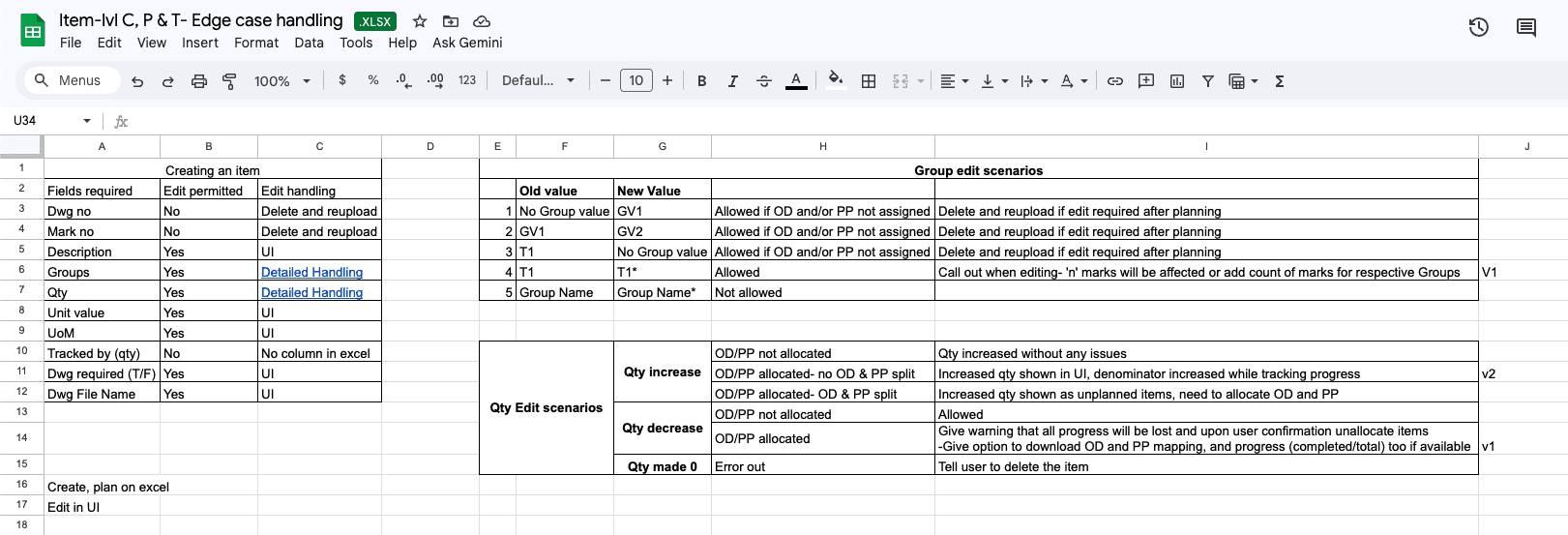

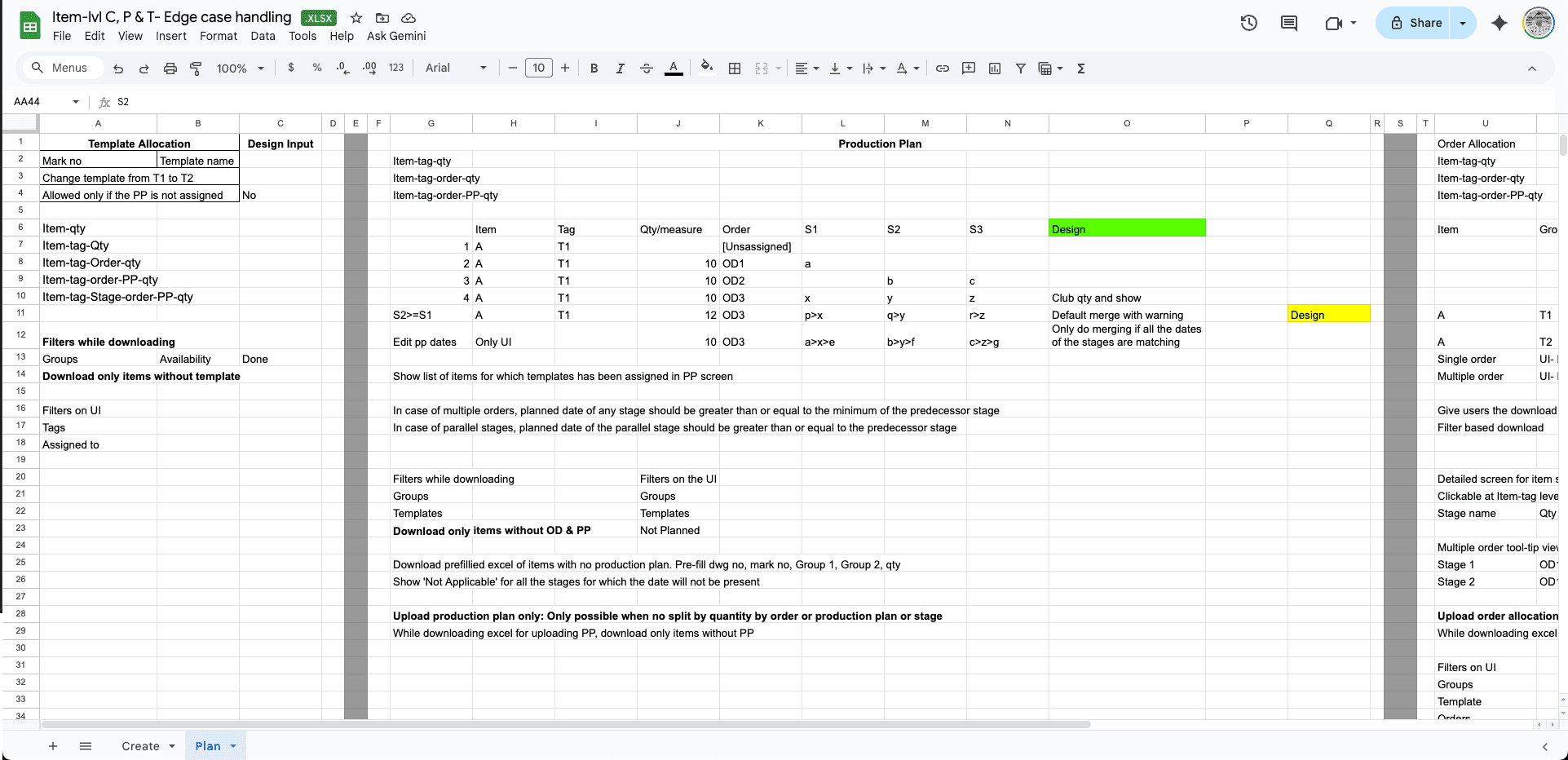

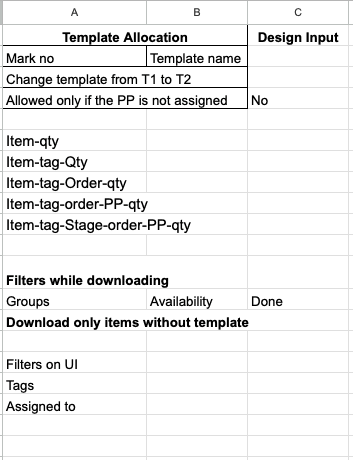

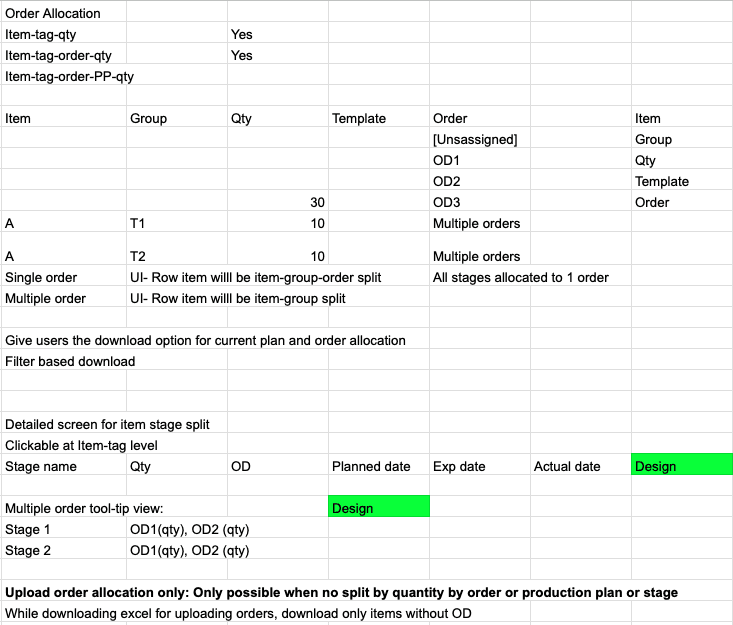

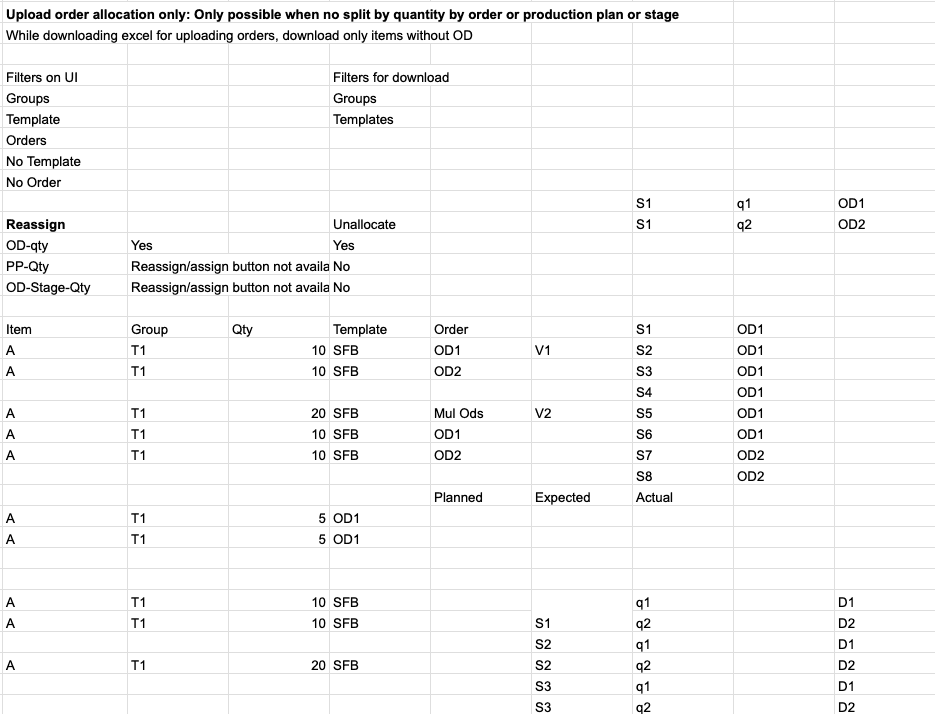

Item-Level Planning

I introduced Item-Level Planning so teams could manage small runs independently without disrupting entire batch schedules.

Planners could now create, allocate, and track items individually. Each stage of production could be linked to a different supplier and order, cutting setup time per contract

from 40 minutes to 12 minutes.

Planners wanted finer control to adjust smaller orders without affecting entire batches.

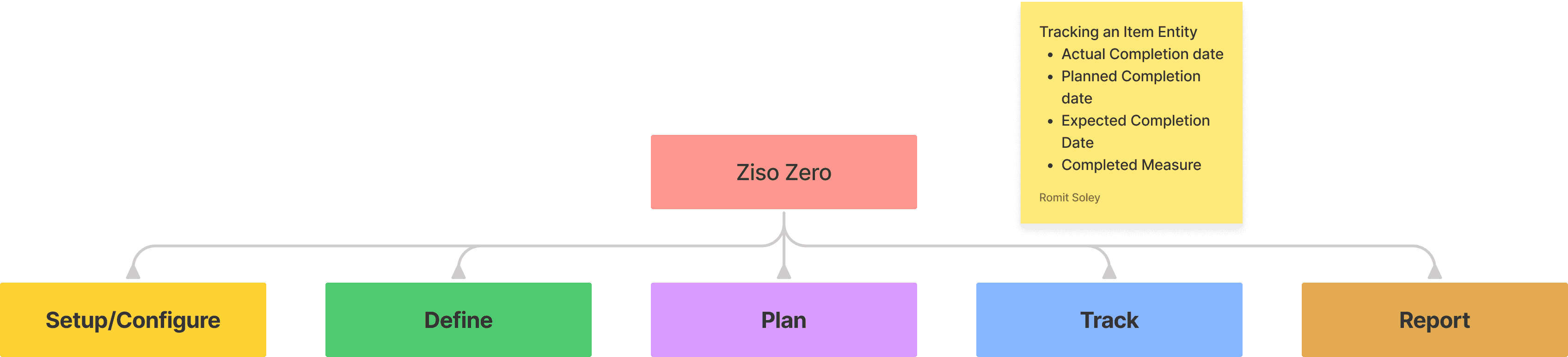

03

Modular Architecture

I restructured ZISO as a modular system to let teams scale, customize, and work across multiple business units with shared visibility.

All actions were reorganized into four modules: Configure, Define, Plan, Track, reducing cognitive load and onboarding time for new users by 70%.

We restructured ZISO as a modular system so teams could scale and customize faster.

IMPACT

Precision turned into measurable progress

For the first time, planners, program managers, and leadership shared a single, real-time source of truth.

+236

%

Teams across five BUs adopted ZISO within one quarter

+48

%

Manual QA checks dropped by almost half

70

%

New users completed setup tasks in under

2 hours

HOW DID WE GET THERE?

Process

I worked closely with engineers to validate every change through weekly design–dev syncs and workflow reviews. Each discovery informed design refinements that simplified flows, automated dependencies, and prioritized visibility over control.

Workshop

Setup

OUTCOME

Aligned roadmap for Phase 1

DURATION

3 hours

TOOLS

FigJam

Excel

PRD

UXR

Systems Audit

Diary Study

Secondary Research

Usability Study

PARTICIPANTS

2x PMs

3x Planning Engineer

5x Developers

3x QA

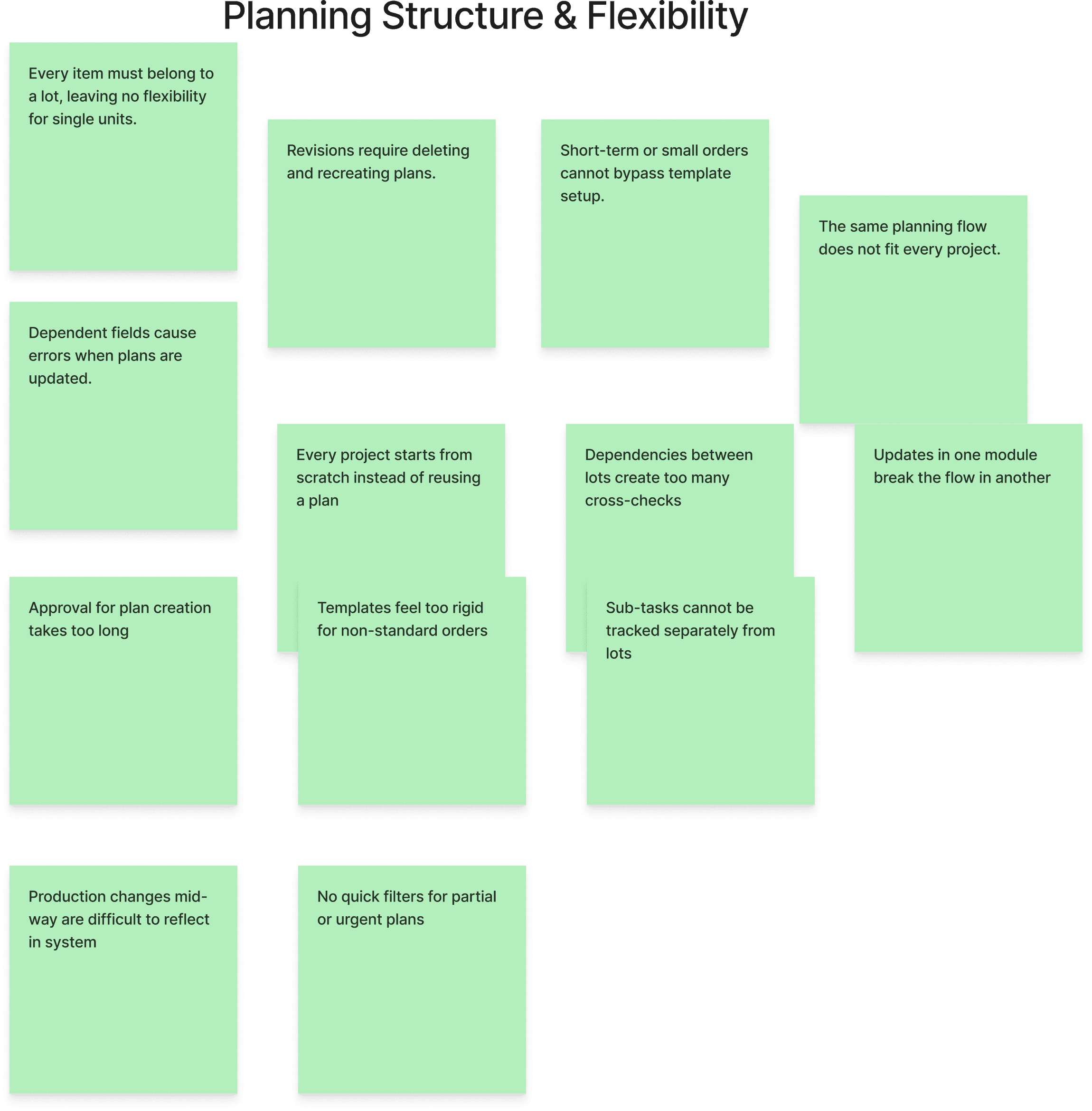

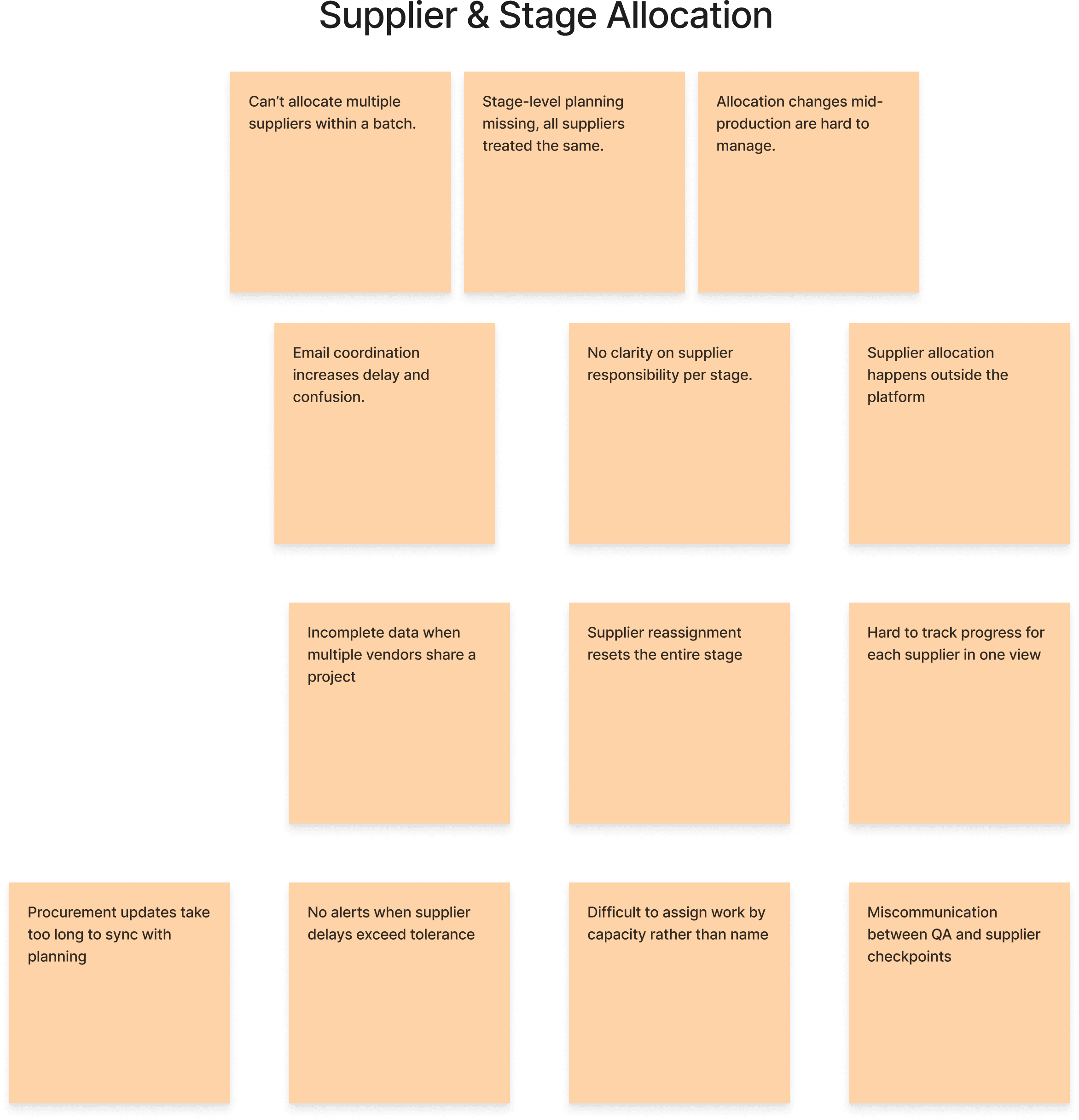

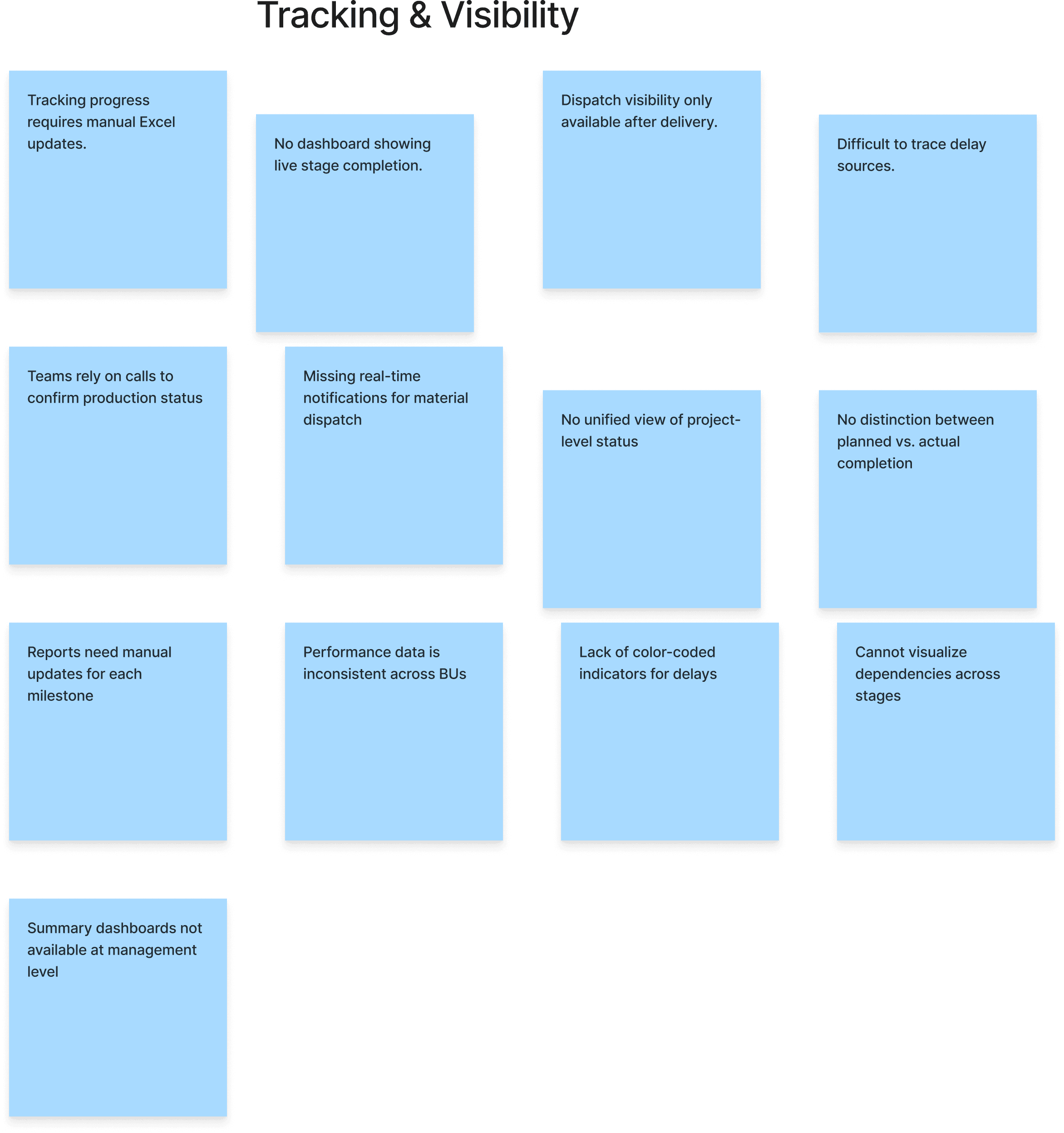

During development, several deeper systemic issues emerged:

SYSTEMS AUDIT

Fragmented Execution

Disconnected stages and siloed tools made end-to-end production tracking slow and error-prone. Tracking gaps increased setup time by 3–5 days per project and

forced 65% of teams to rely on manual workarounds.

DIARY STUDY

Reactive Decision Loops

Teams relied on delayed updates, forcing them to respond reactively rather than plan proactively. Decisions lagged by 18–24 hours, leading to ~12% slower order completion and missed delivery windows.

SECONDARY RESEARCH

Template Fatigue

Rigid input forms and repetitive setup steps slowed new project onboarding and adoption. 69% of project setups required manual data entry, increasing setup time by 30–40%

per order.

USABILITY STUDY

Dependency Overload

Supplier and internal updates depended on manual coordination, creating workflow bottlenecks. Only 16% of projects had complete tracking, resulting in ~22% reporting discrepancies and delayed issue detection.

These recurring inefficiencies shaped the strategy for ZISO Zero, helping me prioritize what to fix first.

Strategy & Planning

After collecting evidence from multiple teams, I translated research insights into a clear plan focused on priority and impact.

EXPERIENCE STRATEGY

Designing flexibility into factory planning

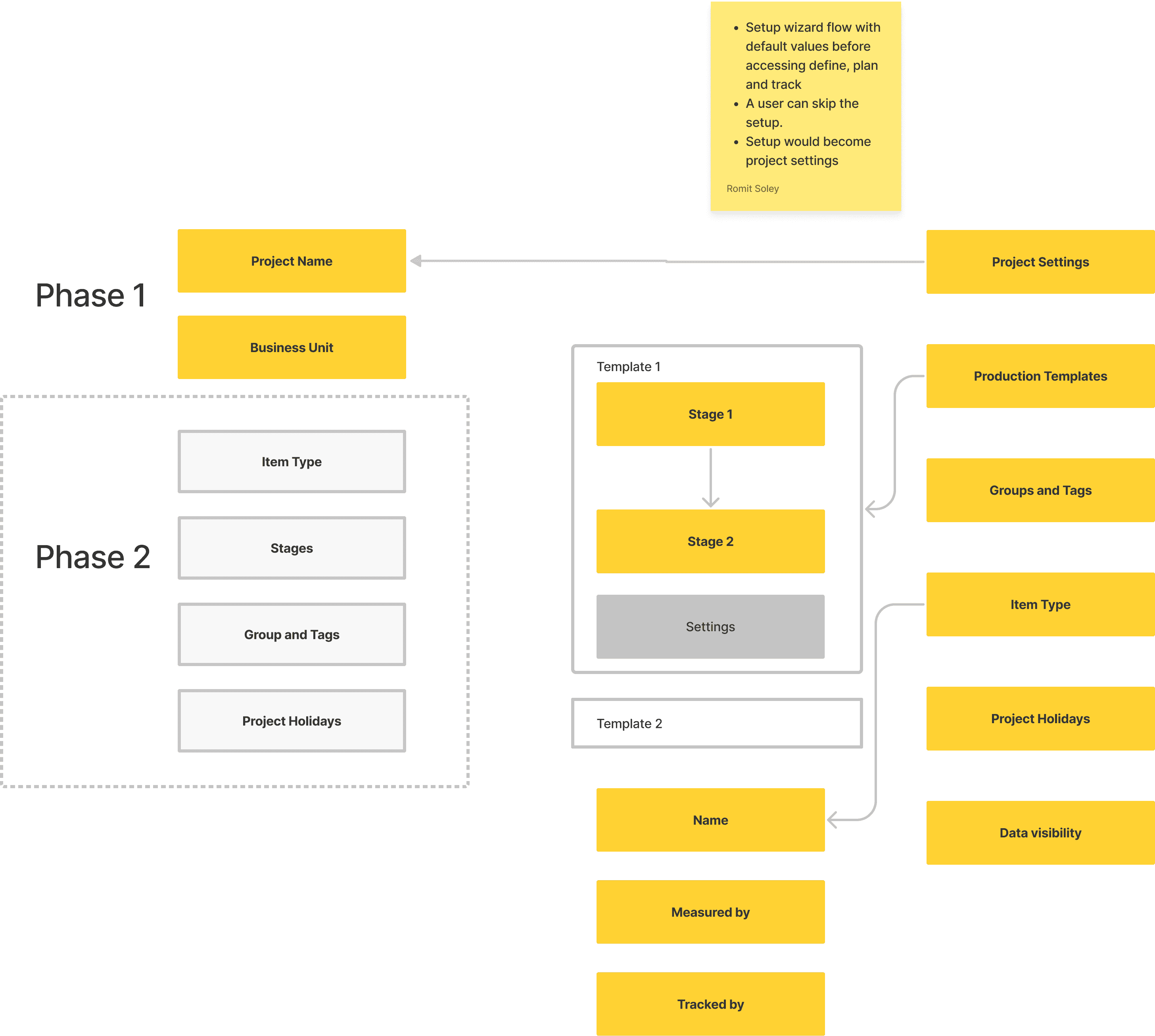

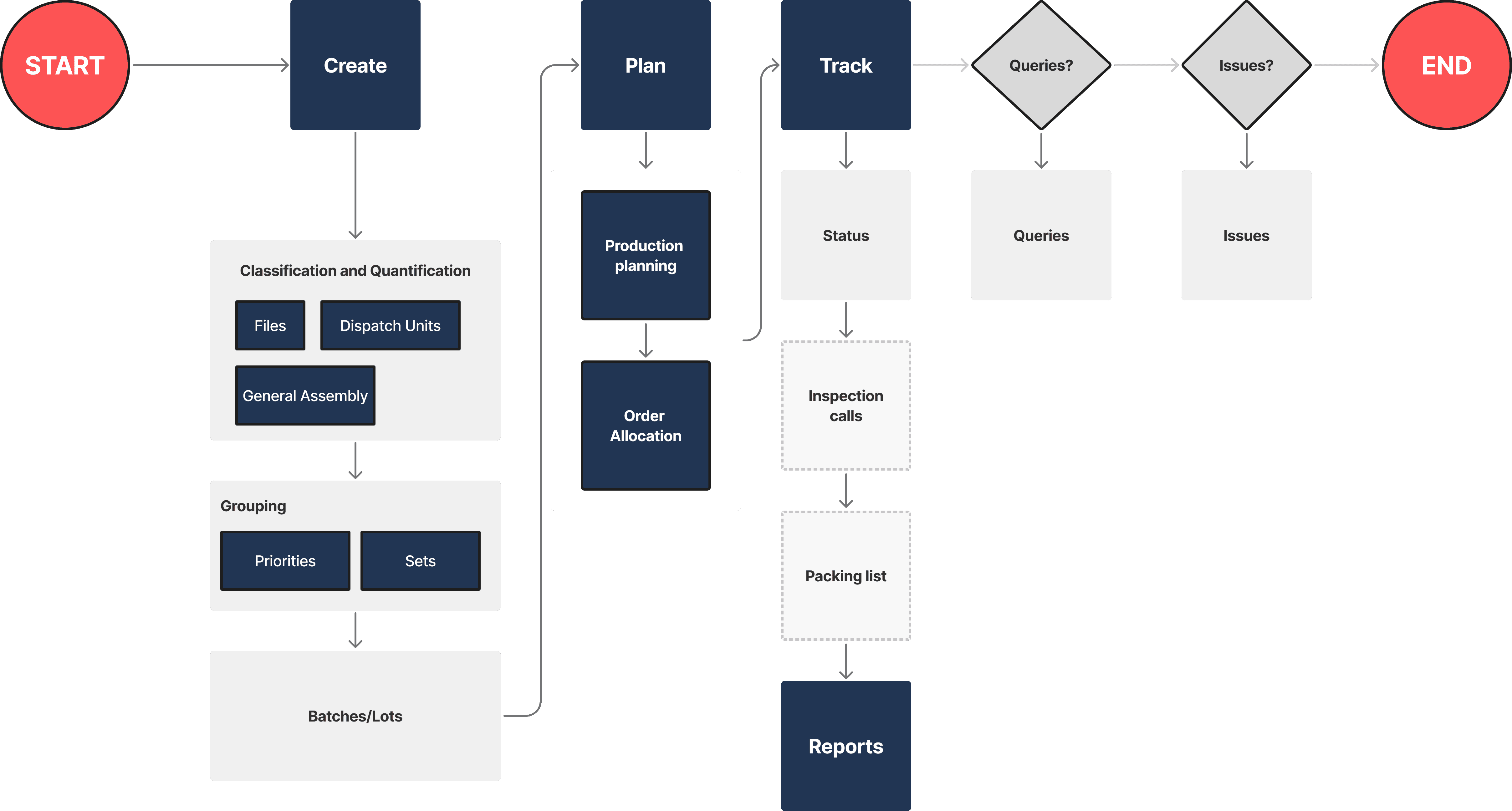

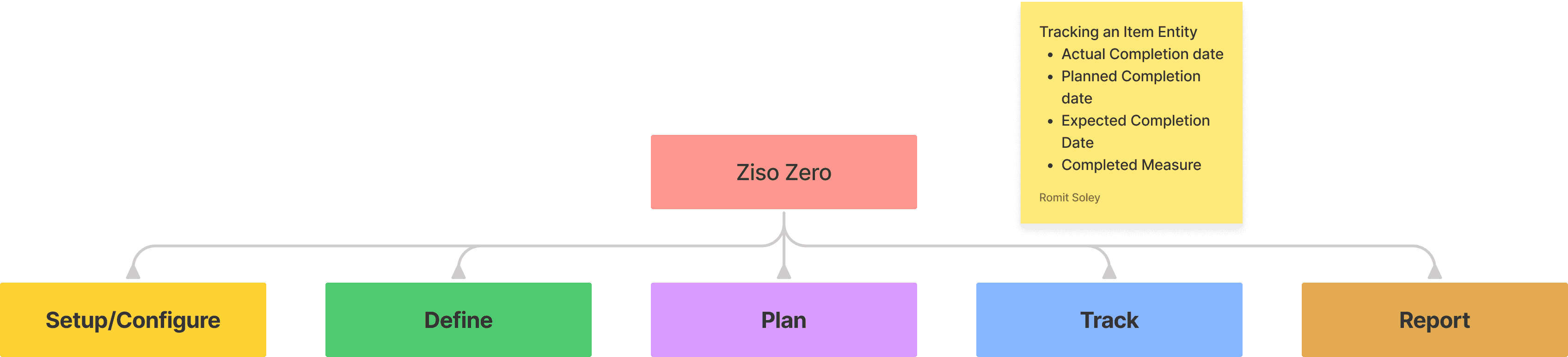

I defined ZISO’s structure as four modular layers — Configure, Define, Plan, and Track.

This modular setup made it easier to scale horizontally and onboard new business units.

Each layer worked independently while sharing data seamlessly across the system.

Configure

BU level settings to allow smoother and faster setup of projects on ZISO

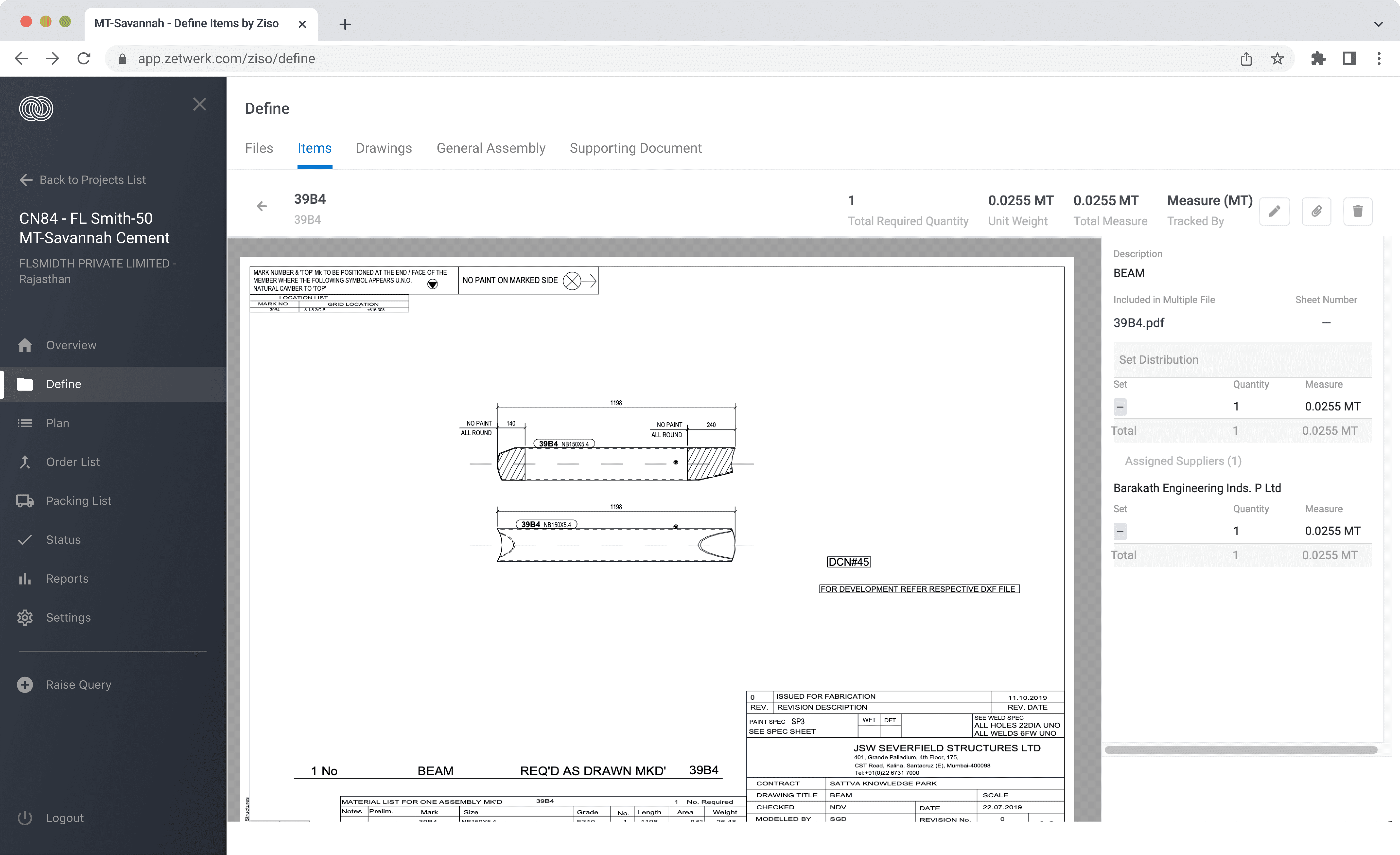

Define

Defining the various attributes of the item to be used during planning and tracking

Plan

Plan out the entire item journey from raw material to the finished good complete with process, timeline, etc.

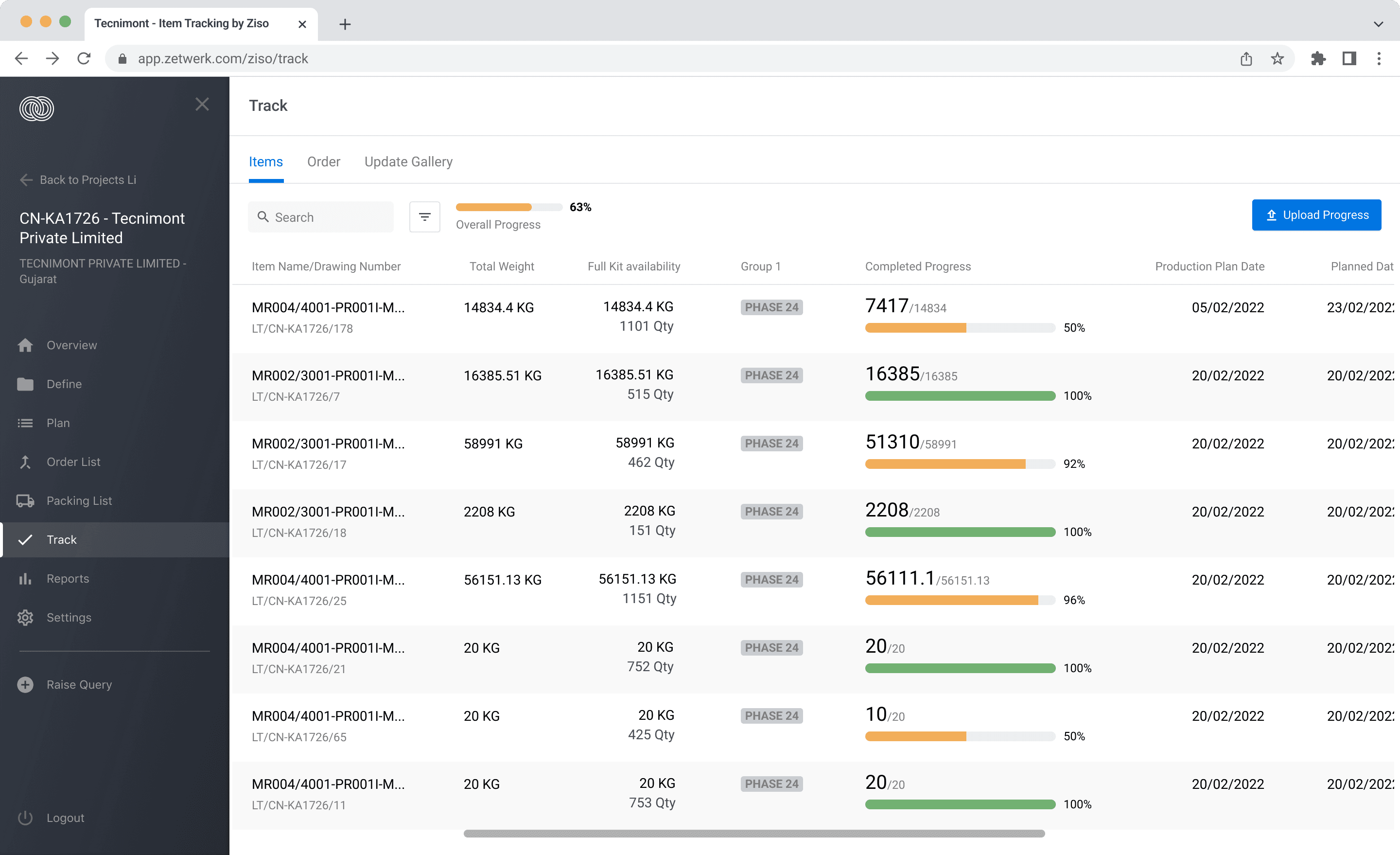

Track

Compare the progress of the item against the set plan

Using insights from the ZISO 2.0 PRD, I reframed the goal from improving accuracy to enabling flexibility so every business unit could plan differently without rebuilding the system each time.

INFORMATION ARCHITECTURE

Simplifying supplier coordination

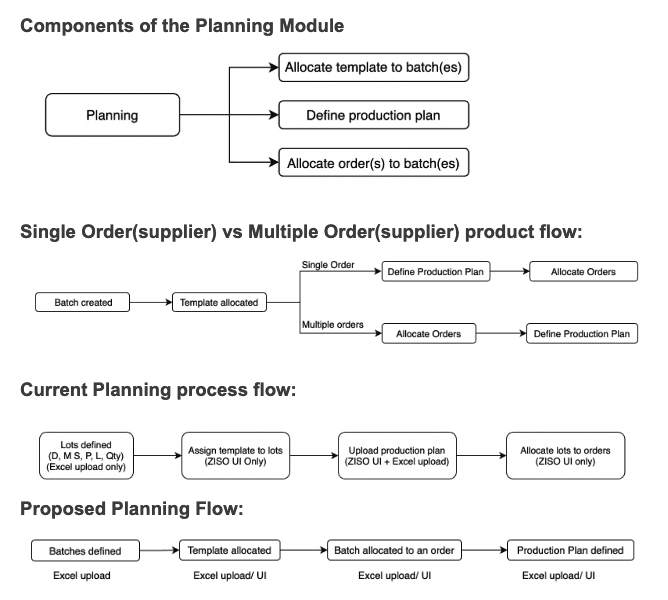

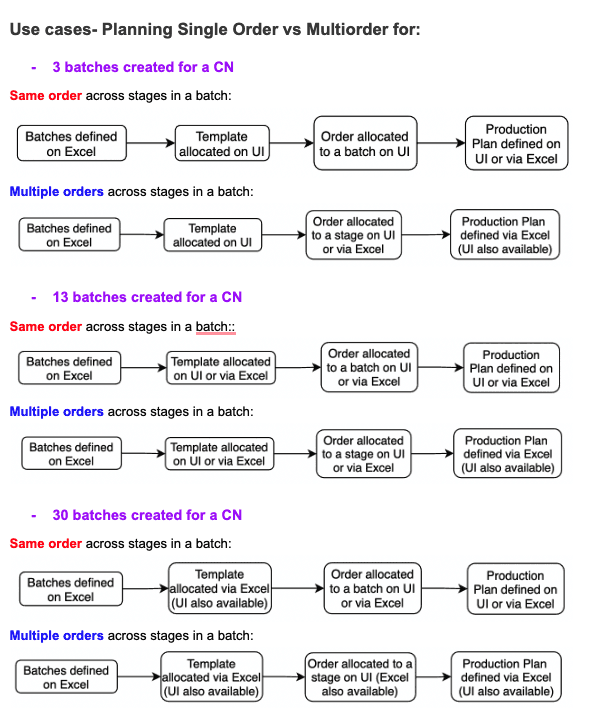

Reviewing the Planning Module PRD revealed deep dependencies between supplier assignment, template setup, and production planning.

A visual dependency map helped identify where users got trapped in redundant steps.

I restructured the flow to allow stage-level order allocation, making supplier coordination faster and easier to manage.

This simplified architecture later became the backbone for ZISO’s planning experience.

ROADMAP DEFINITION

Focusing on adoption levers

While reviewing the ZISO 2.0 backlog, I led a strategy session to prioritize features by operational value. We focused on item-level tracking, multi-supplier allocation, and modular configuration, the three design levers most likely to boost adoption.

Participants used FigJam to capture operational pain points from their daily workflows.

Over 60 insights were gathered and grouped into four validated clusters derived from the Planning Module and PRD documents.

PHASE 1

Planning

Enabled item-level planning to remove rigid lot limits

Separated template setup, order allocation, and planning steps for speed

Introduced stage-based allocation to share batches across orders

Simplified item creation to cut manual entry and setup time

Accelerated onboarding for new business units

PHASE 2

Configure and Reporting

Designed custom dashboards for real-time performance tracking

Strengthened transparency and adaptability across operations

Enabled split tracking for dispatch and exception handling

Created workspace views tailored to each role

Added configurable settings at the business-unit level

Lower-impact features such as advanced reports were moved to later phases, allowing early pilots to validate results faster across two business units.

CROSS-FUNCTIONAL ALIGNMENT

Creating a shared language for manufacturing data

Each business unit (fabrication, precision, and assembly) tracked production differently, which made it difficult to decide what to build first.

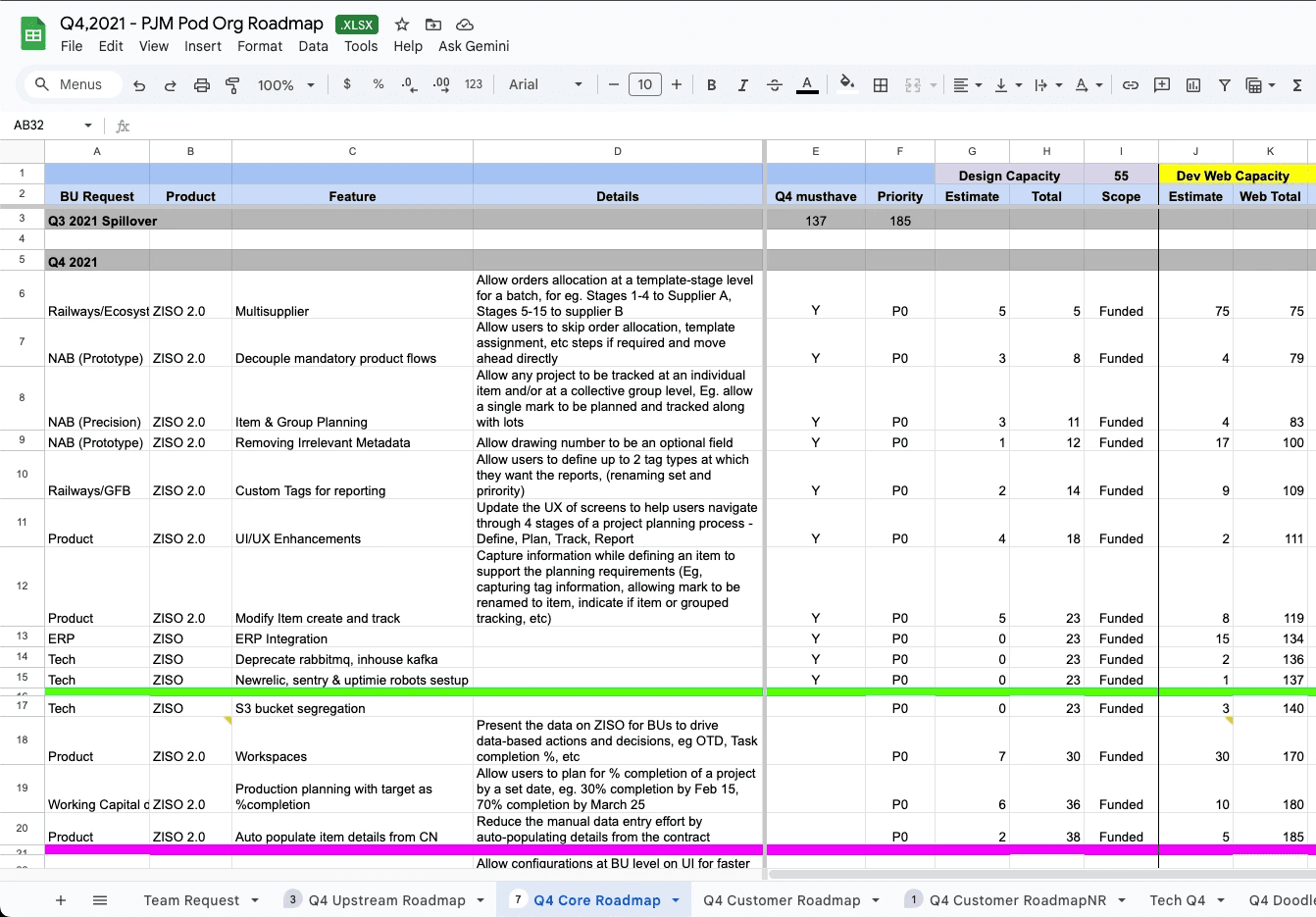

Using insights from the PJM Q4 Planning document, I facilitated a session with planners, engineers, and managers to align roadmap priorities. Each initiative was scored for impact, feasibility, and scope, creating one shared roadmap.

+48

%

Fewer reporting discrepancies

+30

%

Faster feature

rollout approval

100

%

Alignment on

Phase 1 priorities

We scored initiatives by impact, feasibility, and scope, then mapped them into quarterly phases. This collaboration aligned expectations across teams, reduced dependency conflicts, and created a consistent foundation for future ERP integration.

Roadmap created using inputs from the PJM Q4 Planning document.

Each feature was ranked by impact and feasibility to balance capacity and business priorities.

Ideation

After aligning on priorities, I focused on exploring how ZISO could evolve into a faster, more connected workflow across planning, tracking, and reporting.

CONCEPT GENERATION

Exploring new ways to plan at scale

We began ideation by using rough Excel layouts instead of traditional sketches. This allowed us to quickly test how item-level and stage-based planning could work within the existing system.

By experimenting with data relationships and workflow logic, we validated ideas faster and collaborated more effectively with developers.

Since our components were already established, we focused on designing behavior, not redrawing UI. The result was a clear direction for a flexible planning model that adapts to both small runs and complex, multi-stage projects.

SYSTEM MAPPING

Connecting planning logic across modules

To align multiple teams, I mapped how information moved across Create, Plan, Track, and Report modules.

Using Excel-based flow diagrams, we visualized how supplier data, order progress, and production status needed to sync in real time.

This revealed where dependencies created delays and guided us toward a cleaner, scalable system structure that matched how planners actually worked.

INTERACTION PRINCIPLES

Designing clarity within known patterns

Instead of creating new UI components, we refined how existing patterns guided decision-making. The goal was to make planning more intuitive by improving hierarchy, context, and pacing within familiar layouts.

We defined three principles that shaped every interaction:

Show relevant context before any action.

Keep forms light and progressive

Let users expand complexity only when needed

These principles kept the experience consistent and predictable across ZISO 2.0 while supporting faster, clearer decisions.